CAPABILITIES

ENGINEERING SERVICES

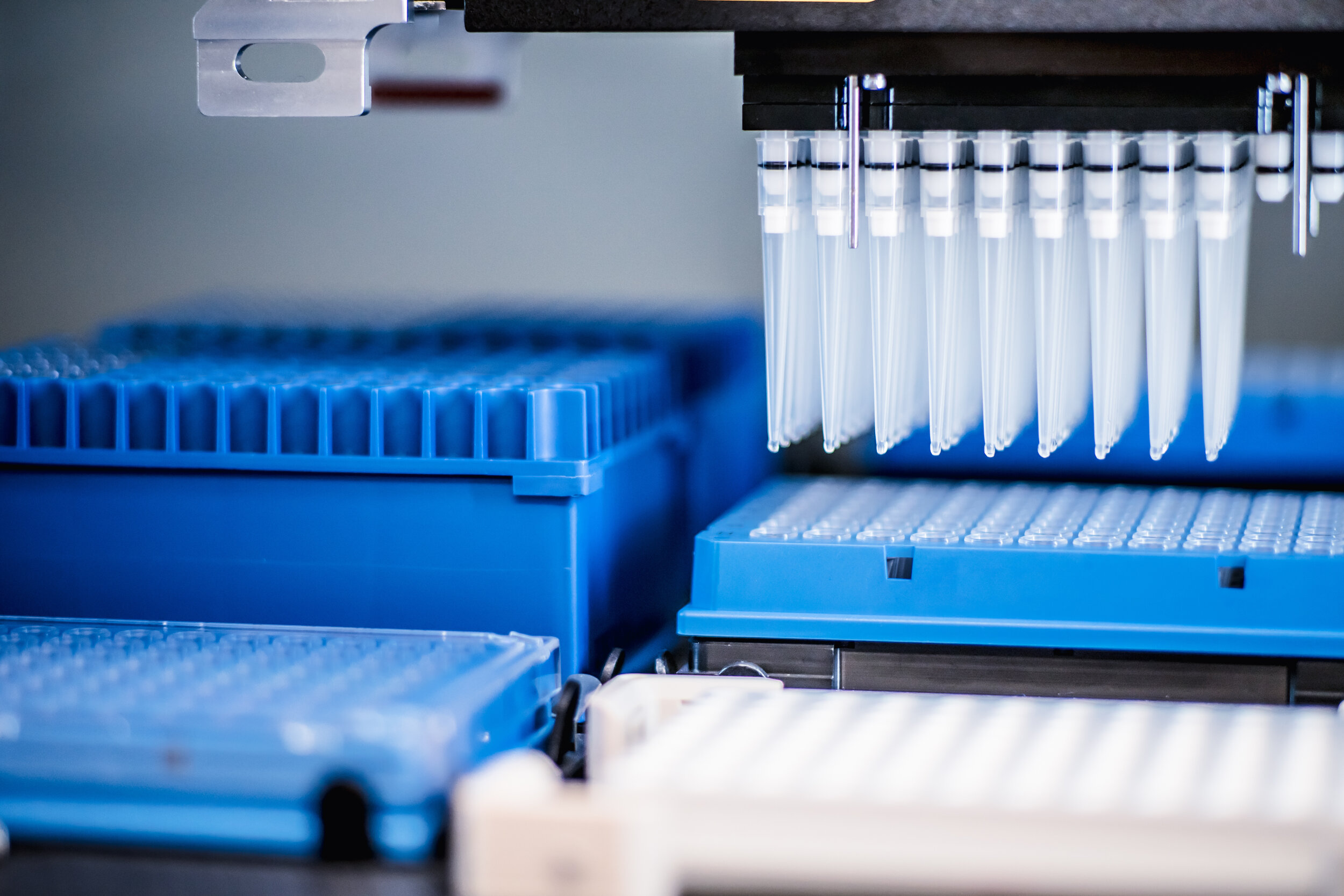

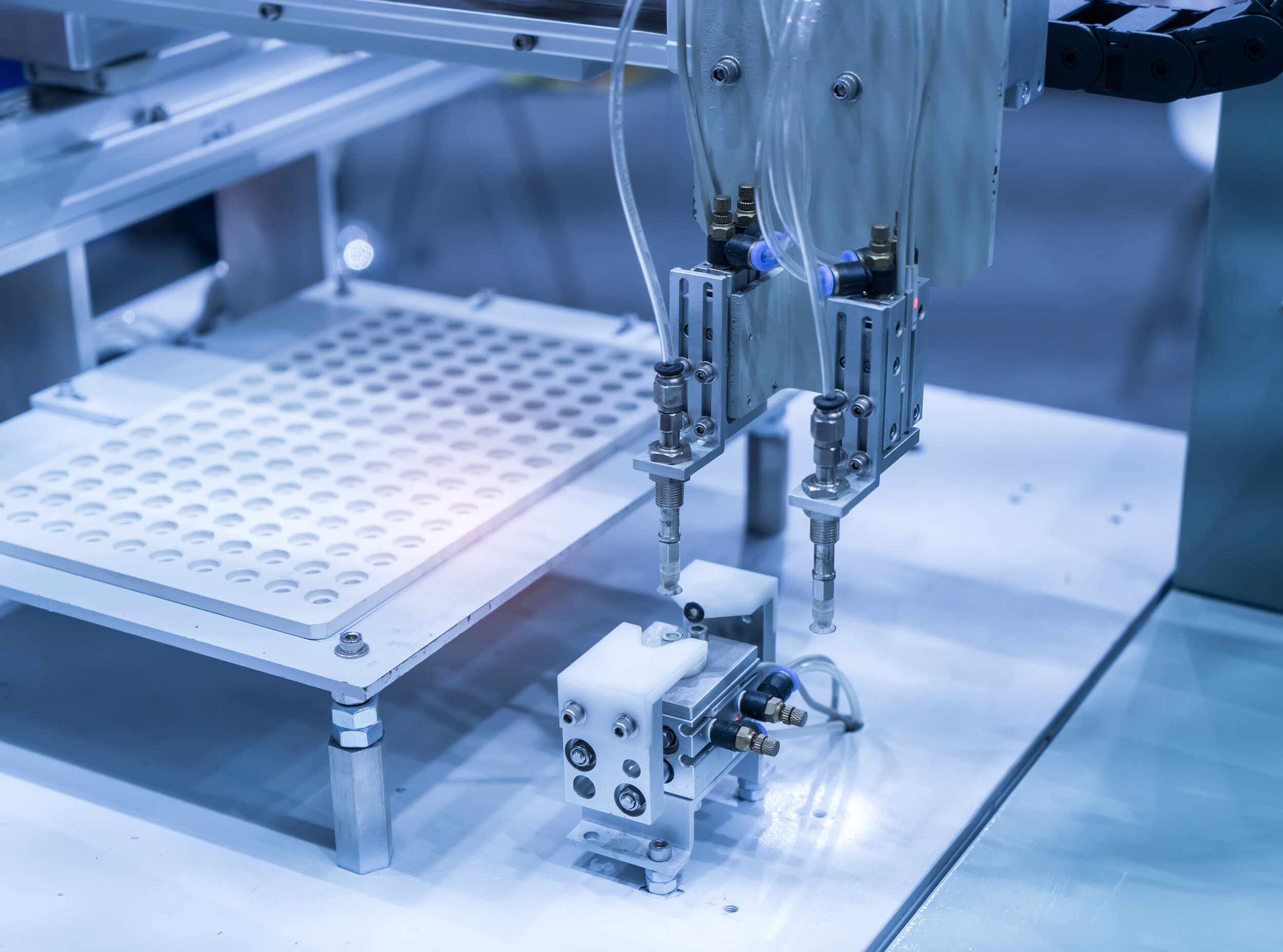

TAILORED TO MEET YOUR AUTOMATION NEEDS

-

Automation consulting services

Proof of Concept & Prototyping

Custom automation Design and Build

Custom automation Build to Print

Installation, customized training and support

-

Robotics & Machine Vision support

Artificial Intelligence (AI) including model training for deep learning vision applications

Custom software development and Integration of off-the-shelf software

IIoT integration: collecting and applying data to real-time processes

Statistical process controls, traceability, and data analytics

-

In-depth knowledge of GAMP 5 guidelines for automation systems

Comprehensive documentation lifecycle: URS, FS, DS, IQ, OQ, PQ, and traceability matrices

Compliance with cleanroom requirements

-

Experience with automation systems designed for hazardous and classified areas

Selection and integration of explosion-proof components, enclosures, and intrinsically safe designs

Compliance with electrical and process safety standards in flammable or volatile environments

-

Expertise in laser cutting and laser marking systems for high-precision, permanent part identification in regulated environments

Implementation of automated laser welding solutions for consistent, high-quality joins in metals and medical-grade materials

Expertise in FDA/CDRH reporting and compliance

ENGINEERING SERVICES

TAILORED TO MEET YOUR AUTOMATION NEEDS

Automation Project Leadership

Automation consulting services

Proof of Concept & Prototyping

Custom automation Design and Build

Custom automation Build to Print

Installation, customized training and support

Advanced Automation & Data

Robotics & Machine Vision support

Artificial Intelligence (AI) including model training for deep learning vision applications

Custom software development and Integration of off-the-shelf software

IIoT integration: collecting and applying data to real-time processes

Statistical process controls, traceability, and data analytics

GAMP Documentation Process

In-depth knowledge of GAMP 5 guidelines for automation systems

Comprehensive documentation lifecycle: URS, FS, DS, IQ, OQ, PQ, and traceability matrices

Compliance with cleanroom requirements

Hazardous Environment & Regulatory Compliance

Experience with automation systems designed for hazardous and classified areas

Selection and integration of explosion-proof components, enclosures, and intrinsically safe designs

Compliance with electrical and process safety standards in flammable or volatile environments

Integration of Laser-Based Solutions

Expertise in laser cutting and laser marking systems for high-precision, permanent part identification in regulated environments

Implementation of automated laser welding solutions for consistent, high-quality joins in metals and medical-grade materials

Expertise in FDA/CDRH reporting and compliance

OUR PROCESS

Our engineering team closely collaborates with you over all phases of an automation project to mitigate risks and cost. We work on both design & build and build-to-print projects. Our standard automation development process includes but is not limited to following steps.

Concept Development & Prototyping

Risk Assessment & Regulatory Compliance Evaluation

Mechanical & Electrical Design

Fabrication & Assembly

Simulation & Programing

MES Integration

Commissioning

Documentation

Installation & Support